Properties and Advantages

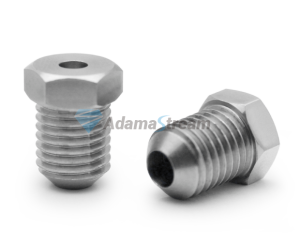

- High Durability: Tungsten carbide’s excellent hardness (approximately 9 on the Mohs scale) ensures that these nozzles maintain their performance and integrity over long periods of operation, even in extreme conditions.

- Superior Wear Resistance: Perfect for handling abrasive media such as aluminum oxide, glass beads, silicon carbide, and other harsh materials, the WC nozzles can endure prolonged exposure to abrasive particles without significant degradation.

- Cost-Effective: While providing longer service life than nozzles made from softer materials (such as steel or ceramic), tungsten carbide nozzles also help reduce overall maintenance and replacement costs.

- Precision Engineering: These nozzles are manufactured with strict tolerances to ensure a consistent flow pattern and optimum performance during abrasive blasting processes, delivering efficient and effective cleaning or surface preparation.

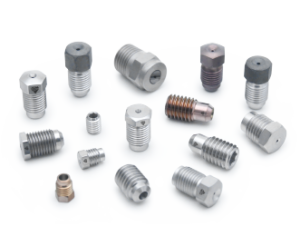

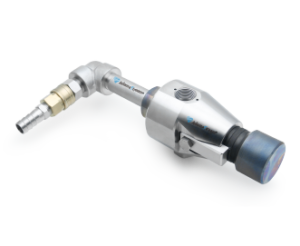

- Versatile Applications: Suitable for a wide range of industries, including metalworking, automotive, construction, and shipbuilding, WC nozzles are commonly used for surface cleaning, rust removal, deburring, and surface preparation prior to coating.

Available For Multiple Media

- steel shot

- steel grit

- quartz sand

- glass beads

- silicon carbide

- alumina

- black diamond

- garnet