Product Advantages

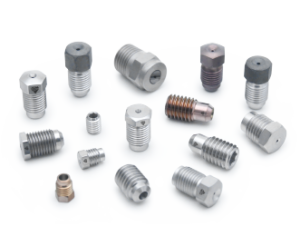

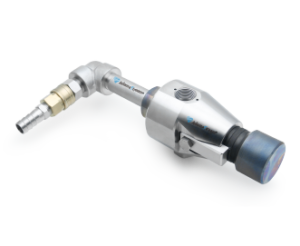

- Efficient Separation: The precisely designed nozzle shape and optimized fluid dynamics ensure efficient liquid separation during the centrifugal process.

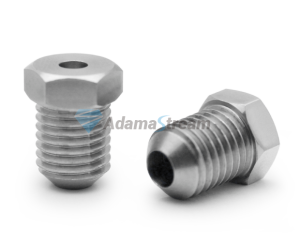

- Long Service Life: Superior wear resistance and corrosion resistance significantly extend the nozzle’s service life, reducing replacement frequency and maintenance costs.

- Stable Performance: Maintains consistent performance under high-temperature and high-pressure conditions, ensuring the continuity and reliability of the centrifuge process.

Material Characteristics

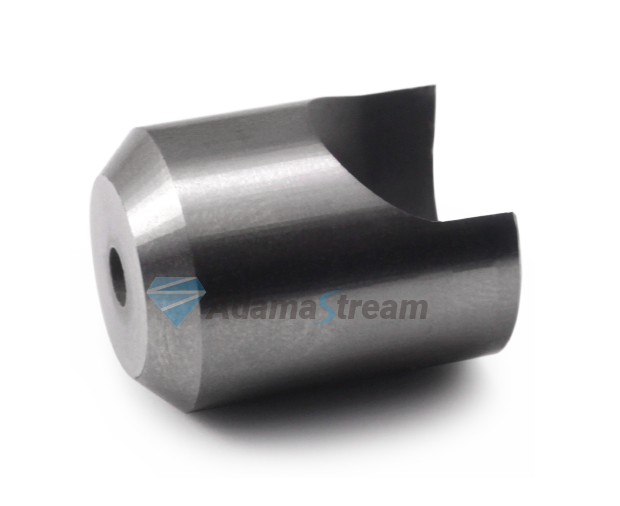

- High Hardness: With a hardness rating typically above 90 HRA, tungsten carbide ensures prolonged durability and resistance to wear, even under high-speed centrifugal operations.

- Corrosion Resistance: Tungsten carbide offers excellent resistance to chemical corrosion, maintaining stability in acidic, alkaline, and other harsh chemical environments.

- High Strength: Maintains mechanical strength and integrity under high temperatures and pressures.

Applications

- Chemical Industry: Used for liquid-solid separation, waste liquid treatment, and product purification in chemical production processes.

- Food Processing: Ideal for juice clarification, dairy product separation, and edible oil refining in the food industry.

- Mineral Processing: Utilized in slurry separation and mineral purification in mineral processing.

- Pharmaceutical and Biotechnology: Employed for cell separation, protein purification, and other bioproduct processing in pharmaceutical manufacturing and biotechnology.