Product Advantages

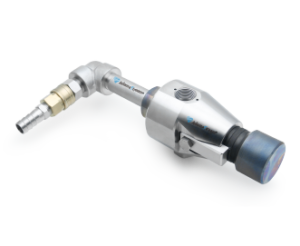

- Efficient Yarn Texturing: The precision-engineered design of our Texturing Nozzles ensures optimal air flow and yarn texturing, resulting in high-quality, consistent yarns.

- Extended Service Life: The superior wear resistance of tungsten carbide reduces the frequency of replacements and maintenance, offering long-term cost savings.

- Stable Performance: Ensures reliable operation even in demanding high-temperature and high-pressure conditions, essential for continuous textile production processes.

Material Advantages

- Tungsten Carbide Durability: Tungsten carbide is known for its exceptional hardness, typically above 90 HRA, providing superior wear resistance and extending the nozzle’s service life significantly.

- Corrosion Resistance: This material offers excellent resistance to chemical corrosion, maintaining its integrity and performance in harsh environments.

- High Strength: Maintains mechanical strength under high temperatures and pressures, ensuring consistent and reliable operation.

Applications

- Textile Manufacturing: Widely used in air texturing processes to produce textured yarns from synthetic and natural fibers. Suitable for creating high-quality air-textured yarns (ATY).

- Garment Production: Ideal for producing yarns used in high-elasticity, soft, and voluminous fabrics, enhancing garment comfort and appearance.

- Home Textiles: Used in manufacturing blankets, bedding, and other home textiles, providing excellent hand feel and texture.

Related Keywords

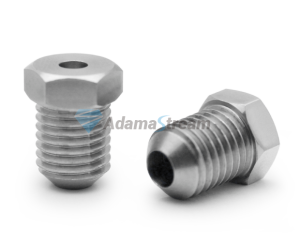

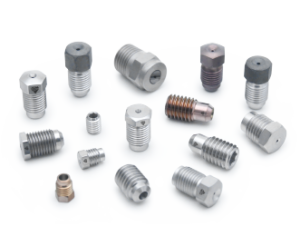

- Texturing Nozzle

- Texturing Jet Nozzle

- ATY Jet Nozzle

- ATY Jet Nozzle in Ceramic

- ATY Jet Core

- Air Texturing Nozzle

- Air Jet Texturing